Commonly called “stuff up plates” were initially used to hide “stuff ups” such as recessed downlight holes cut too large.

We’ve all heard anecdotes of 1st year apprentice being left on site to cut holes for recessed downlights, which he did diligently and efficiently, making all the cutouts by the time the electrician was back. To the electrician’s surprise the holes were cut to the outer diameter, not the downlight cutout as specified by the manufacturer. The story has it that the whole job was saved by the use of larger recessed downlights or the use of “stuff up plates”, depends on who is telling the story. The apprentice is now a qualified electrician or now works at a hardware store offering advice. Again, it depends on who is telling the story.

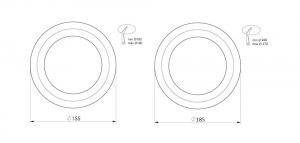

What do stuff up plates look like? They look like a ring. They look like this:

What does the finished product look like? Something like this:

Stuff up plates became so popular that some manufacturers began seriously making them to fit their recessed downlights so that they can cover a wide range of cutouts.

It’s all so simple: Make a small downlight fit into a big hole.

Double stuff up plates are also available, making it possible to convert a twin halogen downlight into a twin LED downlight.